All published articles of this journal are available on ScienceDirect.

Optimization of Extraction Process for Polysaccharide in Salvia Miltiorrhiza Bunge Using Response Surface Methodology

Abstract

This study was aimed to optimize the extraction process for Salvia miltiorrhiza Bunge polysaccharide using response surface methodology The results showed that four operating parameters including microwave power, microwave time and the particle size had notable effects on the polysaccharide extraction of Salvia miltiorrhiza Bunge. The effects could be ranked in decreasing order of importance as follows:. Microwave power > microwave time > the comminution degree. The optimal extraction parameters were determined as 573.83W of Microwave power and 8.4min of microwave time and 67.51mesh of the comminution degree, resulting in the yield of Salvia miltiorrhiza Bunge polysaccharide of 101.161mg / g. The established regression model describing polysaccharide extraction from as a function of the three extraction parameters was highly significant (R 2 = 0.9953). The predicted and experimental results were found to be in good agreement. Thus, the model can be applicable for the prediction of polysaccharide extraction from Salvia miltiorrhiza Bunge.

1. INTRODUCTION

Salvia miltiorrhiza, also known as red ginseng, purple salvia, red roots. And it’s dried roots of Salvia miltiorrhiza. It’s mainly produced in Anhui, Henan, Shanxi and other province. The medicine efficacy was included [1]: blood menstruation, blood stasis and pain, cooling carbuncle, nourishing the nerves. Salvia miltiorrhiza is widely used in food, beverage, and health care products. So it is a natural, Medicinal and Edible material. Modern pharmacological experiments and clinical application of the refined polysaccharide extract from Salvia miltiorrhiza when used for nephropathy induced by amino nucleoside and liver injury model induced by carbon tetrachloride, can reduce urinary protein excretion, serum cholesterol and lipid suppression peroxide concentration increase and improve the ratio of serum albumin and globulin(A/G), and can reduce the liver damage caused by elevated ALT [2]. For further study of its pharmacological activity, structure-activity relationships [3], separation and purification processes will be optimized first.

The extraction method of polysaccharide commonly used [4] was water extraction, alcohol precipitation, ultrasound-assisted, acid or alkali extraction, enzymatic hydrolysis and microwave assisted extraction. Polysaccharides are a class of macromolecular compounds containing many hydroxyl groups. So it can easily soluble in water because of easily form hydrogen bonds with the water molecules. In alcohol, ether, ketone solvents, they form hydrogen bonds with the polysaccharide is not easy. Thus the polysaccharide has lower solubility in a higher concentration of alcohol or ether. Using this principle the polysaccharide will be precipitate when the alcohol solvent added to to an aqueous solution of a large amount of polysaccharide [5]. The Advantages of water extraction and alcohol precipitation method [6] is simple, convenient, low-cost, non-polluting, and suitable for industrial production. The disadvantage is higher extraction temperature, lower extraction rate, a large loss in activity, difficult to purify. Ultrasound causes tissue deformation and rupture, and release contents, so as to promote the dissolution of the active ingredients within the cell, but the high power will cause damage to the polysaccharide structure and the material out of the cells induce the difficulty of separation [7]. Acid, alkali extraction method is only suitable for certain types of polysaccharides, and the pH must be strictly controled. So there are significant limitations to use [8]. Enzymatic method, while effective, but the cost is too high [9]. The microwave has a strong ability to penetrate. Microwave rays through the cell wall in a solvent and reach inside the cell, the solvent and the interior of the cell absorb microwave energy due to high temperature and pressure. When the pressure exceeds the capacity of the cell, the cell walls rupture, and the material inside the cell outflow and is dissolved in solvent. Thus the extraction rate is improved

[10]. Advantages of microwave extraction is simple, high efficiency, no pollution, and the extraction time is short. But the power of this method is consumption, and the polysaccharide structure is easy to be destroyed. Now microwave extraction has become an important means of polysaccharide extraction. Extraction process of the microwave was studied in this experiment, which will provide a basis for the development and utilization of resources Salvia [11].

2. SALVIA POLYSACCHARIDE EXTRACTION AND PURIFICATION

Salvia polysaccharide were extracted by microwave, 95% ethanol alcohol precipitation, sevage method of protein removal method for its purification [12].

10g Salvia powder (accurate to 0.0 001g), extracted with an appropriate volume of 80% ethanol, siphon occurred many times in a Soxhlet extractor until the extract is colorless. Then the 100ml of distilled water was added to the powder, allowed to stand for 10min to wet the material. The microwave power, microwave time was adjusted to extract polysaccharide. This extraction method was repeated a total of three times, and the three extracts were merged. The merged extract was filtrated, and the filtrate was concentrated to about 50ml, dry residue collected to spare. The material was cooled to room temperature and added slowly 280ml 95% ethanol (alcohol concentration of 80%), while stirring rapidly, refrigerator cold 4 ℃ allowed to stand overnight, 4 000r/min centrifugal 10min, the residue was repeatedly washed with an appropriate amount of acetone ventilation air dry, add water to liquid ratio of 1: 1 extract and chloroform: n-butanol (4: 1 by volume) mixture of 2: 1 mix,, centrifuged at 5,000 rpm, 3min, repeat the operation several times, until the junction without white turbidity, take the upper aqueous phase, approximately 40ml, PH is 8.5 (adjusted with sodium hydroxide) was added hydrogen peroxide < 8 ml [13], 50 ° C water bath below 2 h, dried to give crude polysaccharides at 60 ° C.

3. DETERMINATION POLYSACCHARIDE CONCEN-TRATION

Accurately weighed and dried to constant weight glucose 25 mg (accurate to 0.0 001g), plus the amount of distilled water, transferred to a 250 ml flask, add distilled water to the mark, mix, dubbed the concentration of 100 μg / ml of standard glucose solution spare [14].

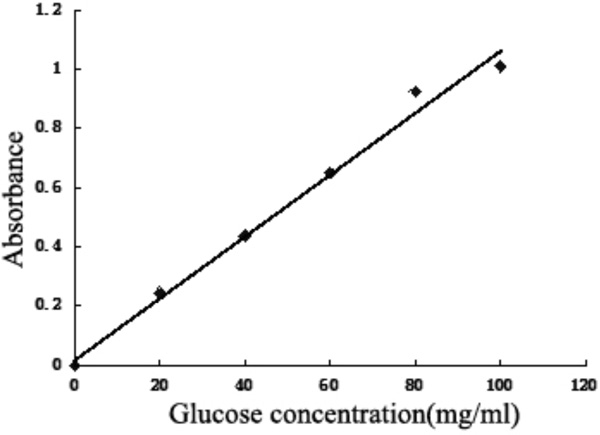

Precise amount of glucose standard solution 0.1,0.2, 0.4, 0.6, 0.8, 1.0 ml in a dry test tube, add water to 1.0 ml, and then were joined by 9% phenol solution 1.0 ml, shake, then adding concentrated H2SO4 5.0ml within 5 ~ 20 S, shake, which operate above 1.0 ml of water as a blank solution. Placed in a constant temperature water bath 40 ℃ 30 min, after removing the cooling 15 min, shake stand 10 min, the absorbance values measured at 485 nm wavelength, Excel standard curve (see Fig. 1), the regression equation, where: y = 0.0104 x + 0.0226, x is the concentration (ug/ml), y is an absorbance [15].

Standard curve of glucose.

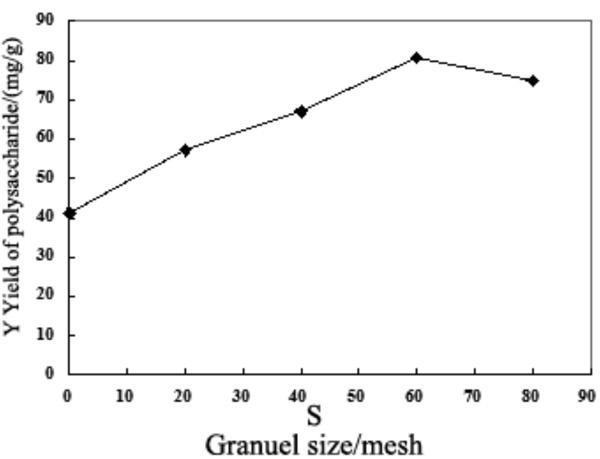

Effect of the comminution degree on yield of Salvia miltiorrhiza Bunge polysaccharide.

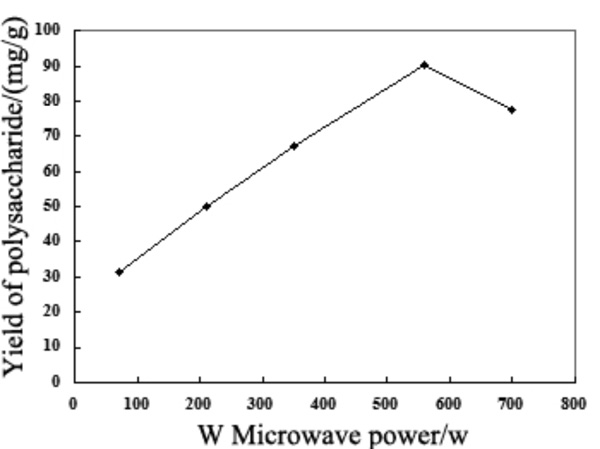

Effect of microwave power on yield of Salvia miltiorrhiza Bunge polysaccharide.

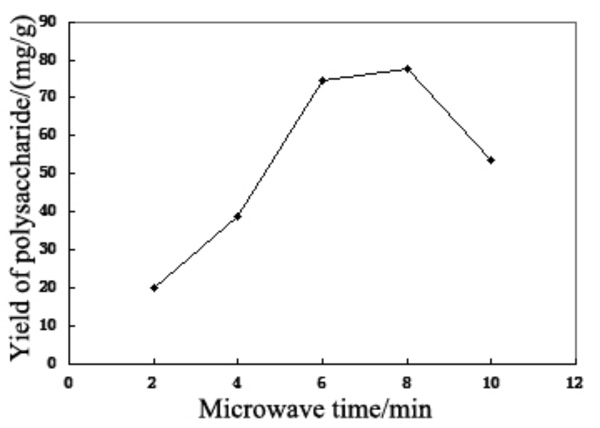

Effect of microwave time on yield of Salvia miltiorrhiza Bunge polysaccharide.

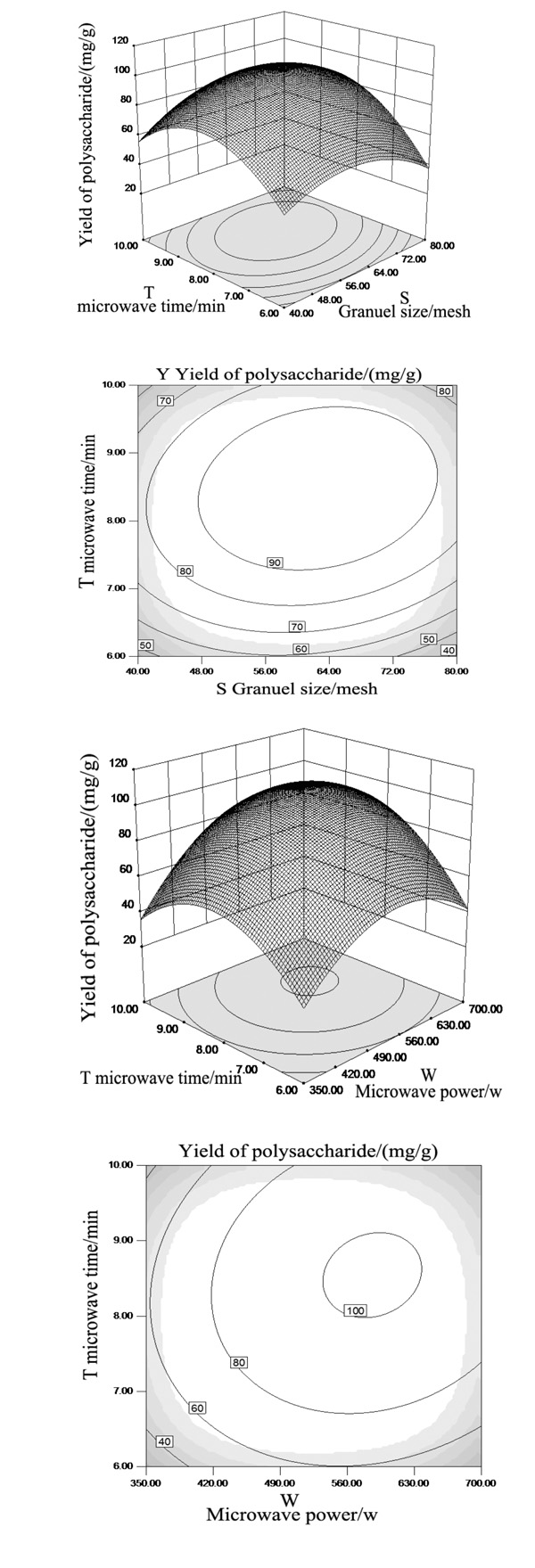

Response surface and contour plots of Salvia miltiorrhiza Bunge polysaccharide extracted at different granule size, microwave power and time.

Box-Behnken experimental design and results.

| No. | S, granule size/mesh | W microwave power/ W | T microwave power/min | Y polysaccharide yield/(mg/g) |

|---|---|---|---|---|

| 1 | 40 | 525 | 10 | 55.6 |

| 2 | 60 | 525 | 8 | 97.8269 |

| 3 | 60 | 700 | 10 | 78.9038 |

| 4 | 80 | 700 | 8 | 77.6538 |

| 5 | 60 | 525 | 8 | 97.9923 |

| 6 | 60 | 525 | 8 | 97.9231 |

| 7 | 40 | 525 | 6 | 45.9423 |

| 8 | 60 | 525 | 8 | 99.75 |

| 9 | 40 | 700 | 8 | 69.3077 |

| 10 | 80 | 525 | 10 | 75.5192 |

| 11 | 80 | 350 | 8 | 39.462 |

| 12 | 60 | 700 | 6 | 39.6346 |

| 13 | 40 | 350 | 8 | 37.8654 |

| 14 | 60 | 525 | 8 | 95.6923 |

| 15 | 60 | 350 | 10 | 38.3269 |

| 16 | 80 | 525 | 6 | 38.25 |

| 17 | 60 | 350 | 6 | 29.1923 |

Analysis of variance for the established regression model.

| Source | Sum of squares | dfa | Mean of square | F value | P value | Significance |

|---|---|---|---|---|---|---|

| Model | 11016.67 | 9 | 1224.07 | 163.12 | < 0.0001 | ** |

| S | 61.44 | 1 | 61.44 | 8.19 | 0.0243 | * |

| W | 1819.65 | 1 | 1819.65 | 242.48 | < 0.0001 | ** |

| T | 1135.99 | 1 | 1135.99 | 151.38 | < 0.0001 | ** |

| SW | 11.39 | 1 | 11.39 | 1.52 | 0.2577 | |

| ST | 190.6 | 1 | 190.6 | 25.4 | 0.0015 | ** |

| WT | 227.02 | 1 | 227.02 | 30.25 | 0.0009 | ** |

| S2 | 1249.35 | 1 | 1249.35 | 166.49 | < 0.0001 | ** |

| W2 | 2535.44 | 1 | 2535.44 | 337.86 | < 0.0001 | ** |

| T2 | 3020.43 | 1 | 3020.43 | 402.49 | < 0.0001 | ** |

| Residual | 52.53 | 7 | 7.5 | |||

| Lack of fit | 44.24 | 3 | 14.75 | 7.11 | 0.0442 | |

| Pure error | 8.29 | 4 | 2.07 | |||

| Cor total | 11069.2 | 16 |

Note: * P <0. 05, said the difference was significant; ** P <0. 01, said the difference was

The exact amount of polysaccharides obtained was 0.1 ml, the volume to 25 ml volumetric flask, add distilled water to the mark. According to the standard curve [7] method, measuring the absorbance calculated polysaccharide quality.

4. EXTRACTION OF POLYSACCHARIDE SALVIA RESPONSE SURFACE EXPERIMENTS

The single factor test results, using Box-Behnken experimental design center, analysis of microwave extraction power, microwave time, particle size effects on income Salvia Salvia polysaccharide yield [16].

4.1. Effects of Particle Size on the Income of Salvia Miltiorrhiza Polysaccharides Yield

At fixed power of 700 W microwave extraction, microwave time 8 min, the impact of different particle size of the resulting mesh 0, 20, 40, 60, 80 on Salvia polysaccharide yield was examined. The results were shown in Fig. (2).

Beginning with decreasing particle size of Salvia, Salvia polysaccharide yield increased significantly, probably because of using smaller particle size, the plant cells were more receptive to have energy and rupture with the same conditions, allowing the polysaccharide yield increased to 60 mesh when the maximum yield, with the mesh after increasing the yield decline, probably because of the small particle size to a certain extent, Salvia particles tend to aggregate into groups, but not conducive to the release of polysaccharides, while a group prone to localized after the temperature increase in the destruction glycan structure [17].

4.2. The Effect of Microwave Power on the Extraction yield of Polysaccharides From Salvia Miltiorrhiza

Using particle size of 80 mesh and microwave time of 8 min, the impact of different microwave power at 70, 210, 350, 560, 700 W on salvia polysaccharide extraction yield was studied. The results were shown in Fig. (3). Using different power to make salvia participate water mixture received different energy at the same time. Then the cell would be ruptured at different fragmentation. As a result, polysaccharide of different sample would be dissolved at different amounts. At beginning the yield of polysaccharide was rising accompany with increased power. The peak value was reached at 560 W. Then even if power is increased, polysaccharides extraction percentage was decreased. Probably when the microwave power is too large, polysaccharide yield would be decreased for too much energy would destroyed it [18].

4.3. Effects of Extraction Time on the Yield of Polysaccharide of Salvia Miltiorrhiza

effects of microwave extraction time on the income Salvia polysaccharide yield was studied at different 2, 4, 6, 8, 10 min at fixed particle size of 80 mesh and microwave power 700 W. The results was shown in Fig. (4).

The yield of polysaccharides was gradually increasing during microwave time from 2 ~ 8 min. But during 8 min to 10 min, the polysaccharide yield was decreased. At beginning the polysaccharides amount increased for more cells ruptured. After the salvia particles was treated for 8 min, the polysaccharide in salvia particles was remained less. Therefore microwave to 8 minutes or more, the polysaccharide structure would be damaged to induce yield decline [19].

4.4. The Establishment of Regression Model

Response surface scheme design and results are shown in Table 1. Each test combination repeated three times. The average value was used as Salvia polysaccharide yield results. The test results was analyzed using Design-Expert 8.05 [20]. The test results in Table 1 were analyzed with multiple regression fitting. A two polynomial regression model of Salvia miltiorrhiza polysaccharide yield with Danshen granules degree X1, microwave extraction power X2, microwave time X3 was got as follow:

Y = -619.37956 + 3.67256S -0.72640W+91 .43712T + 4.82107E-004S*W+0.17257S*T+0.021525W*T-.043064S2-8.01276E-004W2-6.69586T2.

The significant of the regression model was analyzed with variance and coefficient test. The results shown in Table 2.

The results from the regression analysis of variance (Table 2) can be seen, the significance of the model is high, yet the proposed equation was fitting; R 2 = 0.9953, which means that quadratic regression model was set up and this model can be used to analyze and predict the microwave extraction method of polysaccharides from Salvia. It can be seen from coefficient test results of the regression model, W, T, W*T, S2, W2, T2 significantly affected Salvia polysaccharide yield at 0.01 level, S significant impacted Salvia polysaccharide yield at 0.05 level, S*T has no significant effect on Salvia polysaccharide yield . The primary and secondary factors influence on the yield of Salvia polysaccharide were microwave power > microwave time > Salvia granule size [21].

4.5. The Model Analysis of Two-factor Interaction Effects [22]

Any two factors of the regression equation is fixed at zero. Then the remaining two factors was operated by programming in accordance with the resulting binary quadratic regression equation. response surface and contour plots of the interaction of factors obtained by the software analysis [23].

Fig. (5) and combined significance analysis in Table 2, the interaction model between factors S*T and W*T factors was more significant interacted. The significant interaction of S*T may be due to effect of particle size on the dissolution rate of polysaccharides, and microwave extraction time related with the amount of energy absorbed by the cells. While the energy would have a effect on speed of cell broken and polysaccharides dissolution. But when polysaccharides dissolution over, Salvia miltiorrhiza granule was still microwaved. Too much energy it will destroy the polysaccharide structure. And as a result yield declines. So the interaction between granule size and microwave time would changes the yield of polysaccharides. The significance of interaction between W and T may be due to the impact of polysaccharides can complete dissolution for enough microwave time, and the microwave power will affect the rupture speed of cell wall, time will enhance this effect, but too high of the power and too long of the time will cause the accumulation of too much energy. they undermine the polysaccharide structure, thus affecting the yield of polysaccharides.

The optimum extraction conditions by Analysis and calculation of the regression equation was obtained. It was microwave power 573.83 W, microwave time 8.4 min, 67.51 mesh particle size of Salvia. The yield of Salvia polysaccharides extracted under these conditions is 101.161 mg/g.

4.6. Validation Experiments

In order to test the reliability response surface optimizationmethod on the extraction result of Salvia miltiorrhiza polysaccharides, the conditions of optimize was used at microwave power 574 W, microwave time 8.4 minutes, Salvia 70 mesh particle size referring to the actual operation. The parallel verification experiments was done 3 times. the resulting Salvia polysaccharide yield was 100.673 g/g, with small of the theoretical value deviatio, good repeatability, no significant differences, indicating that the use of the model parameters to optimize the response surface method was accurate and reliable.

CONCLUSION

On the basis of single factor experiments, using Box-Behnken design, a quadratic polynomial parameter mathematical model was build for Salvia polysaccharide extraction process. the model was tested reasonable and reliable. It can more accurately predict the Salvia polysaccharide yield, reflecting the effect of the extraction pros and cons. the primary and secondary factors influence on the yield of Salvia polysaccharide were microwave power > microwave time > Salvia granule size. Salvia particle size and power of microwave extraction and microwave extraction and microwave power time interaction on Salvia polysaccharide yield significant effects. The optimal conditions for microwave extraction was: microwave power extraction 573.83 W, microwave time 8.4 min, 67.51 mesh particle size of Salvia, Salvia polysaccharide obtained a yield under these conditions is 101.161 mg/g. Analysis method to obtain the optimal process parameter extraction of Salvia miltiorrhiza polysaccharides by response surface, will provide the reference for the industry improve the study of Salvia miltiorrhiza polysaccharide yield

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

The authors acknowledge the financial support provided by grants from the National Natural Science Foundation of China (No.11102092); Science and Technology Key Project of Education Department in Henan Province (No. 12B130003); and Biochemistry and Molecular Biology Key Discipline of Henan Province.